In the world of apparel manufacturing, the distinction between utilizing off-the-shelf stock for printing and engaging in cut and sew operations marks the difference between customization at a surface level and deep-rooted, brand-specific tailoring. Cut and sew manufacturing involves creating garments from scratch, starting with fabric selection, cutting based on unique patterns, and sewing to create the final product. This contrasts with standard printing on blanks, where pre-made garments are simply embellished with printed designs. The cut and sew process offers unparalleled opportunities for customization and branding, but it also introduces a set of intricacies in sourcing and relationship-building with factories.

Navigating the Complexities of Factory Communication

One of the initial hurdles in leveraging cut and sew manufacturing is establishing contact with the right factories. Unlike many businesses that might have a customer-facing front or a simple lead form for inquiries, cut and sew factories, especially those overseas, often lack easily accessible channels for initial communication. This can be attributed to the industry's focus on production over marketing, leaving potential clients puzzled about how to begin their manufacturing journey.

Moreover, the specialization within cut and sew factories adds another layer of complexity. Many factories focus on specific types of products or materials, meaning that a factory excelling in lightweight summer wear may not be suited for producing high-quality denim garments. Identifying a factory with expertise in the specific product you intend to produce is crucial for ensuring quality and efficiency.

The Art of Sourcing the Right Factory

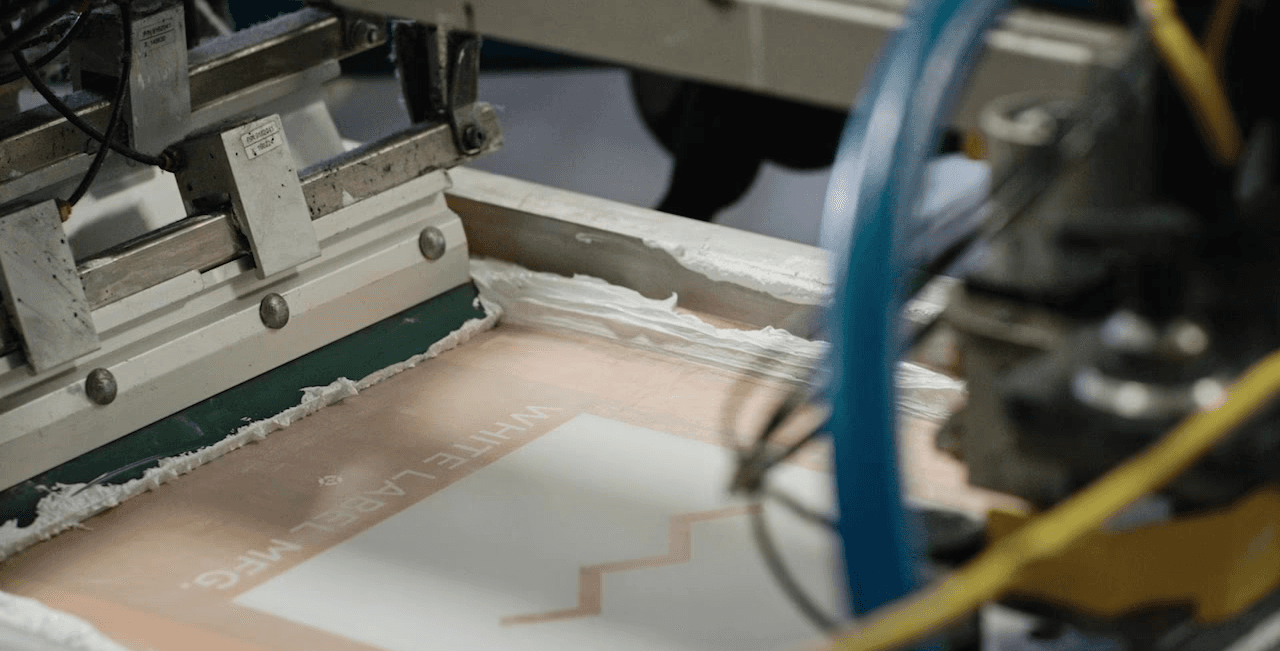

Proper sourcing is both an art and a science, requiring a deep understanding of the product, the market, and the manufacturing landscape. Sourcing companies like White Label MFG play a pivotal role in this process. With established networks of factories specializing in various apparel categories, sourcing companies can bridge the gap between brands and the perfect manufacturing partners.

White Label MFG, for example, not only assists in finding factories with the right specialization but also navigates the intricacies of communication, negotiation, and product development. By representing clients in discussions with factories, White Label MFG ensures that product visions are accurately communicated and that the final products align with clients' expectations. This service is invaluable for brands that may not have the resources or expertise to manage these relationships directly.

Fostering Long-Term Relationships with Factories

Building a lasting relationship with a cut and sew factory goes beyond successful negotiation and effective communication. It involves cultivating a partnership based on mutual respect, understanding, and trust. Here's how brands can build and maintain such relationships:

1. Humanize the Connection: Remember that factories are run by people. Show appreciation for their work, understand their challenges, and respect their expertise. Personal visits, when possible, can significantly strengthen the bond between a brand and a factory.

2. Bring Repeat Business: Factories value clients who provide steady work. Demonstrating loyalty through repeat orders can encourage factories to prioritize your projects and may lead to more favorable terms over time.

3. Develop a Streamlined Workflow: Over time, work on refining the process of product development with your factory. Clear communication, consistent feedback, and a willingness to adapt can lead to a workflow that simplifies cut and sew production for both parties, making the process more efficient with each project.

4. Respect the Factory's Capabilities and Limitations: Understand what your factory does best and design your products with these strengths in mind. Pushing a factory to produce items outside their specialization can strain the relationship and compromise product quality.

5. Invest in the Relationship: Show interest in the factory's long-term success as well as your own. This can involve collaborative projects that benefit both parties, financial incentives for meeting or exceeding quality and timeline expectations, or assistance in areas where the factory seeks to improve or expand.

Transforming Challenges into Triumphs

In the competitive landscape of fashion and branding, the journey from conceptual designs to tangible products is filled with intricate challenges, especially for those venturing into the specialized field of cut and sew manufacturing. This was precisely the scenario PRIME by Logan Paul faced in their endeavor to not just print logos on apparel but to integrate their brand essence into the very threads of style and functionality.

Initially, PRIME placed their trust in a screen printing partner to navigate the complex world of cut and sew. This decision, made with the best intentions, soon revealed its limitations. The partner, skilled in screen printing, found themselves out of depth in the cut and sew domain. Utilizing platforms like Alibaba to connect with overseas manufacturers, their approach lacked the expertise and finesse required for such a specialized task. The result was a prolonged development cycle spanning eight months, culminating in products that fell short of PRIME's high standards.

At this critical juncture, PRIME turned to White Label MFG, drawn by our renowned expertise in developing premium athleisure products. Our reputation for excellence and an established network of specialized factories offered a beacon of hope. White Label MFG wasn’t just another vendor; we were a partner poised to bring PRIME's ambitious vision to life with precision and care.

The collaboration between PRIME and White Label MFG was marked by a seamless fusion of creativity and expertise. PRIME's team provided a rich tapestry of references and mood boards, brimming with ideas and expectations. Our design team engaged in a dynamic exchange with PRIME, translating these visions into a tangible collection. From leggings and tennis skirts to crop tops, windbreakers, and even duffel bags, each product was meticulously crafted. Our process involved developing all art, assets, graphics, and tech-packs for production, ensuring every detail was accounted for.

The strategic partnership with White Label MFG was transformative for PRIME. It provided not only a pathway out of their manufacturing quandary but also unlocked new horizons for their brand. Our extensive knowledge in athleisure, coupled with direct access to our vetted factories, ensured a smooth and successful production process. PRIME now had a reliable and skilled partner, guaranteeing premium cut and sew apparel that met their vision and quality standards at competitive prices.

The successful collaboration between PRIME and White Label MFG set a new benchmark for what brands can achieve with the right manufacturing partner. It’s a testament to the power of combining deep industry knowledge with a network of specialized factories to bring ambitious visions to life. For PRIME, this partnership not only solved an immediate need but also laid the groundwork for future collections, promising a continuous stream of high-quality, innovative apparel.

In the end, the story of PRIME and White Label MFG is more than just overcoming manufacturing hurdles; it’s about the synergy between a brand with a vision and a manufacturer with the means to realize it. Together, we’ve embarked on a journey that transcends the traditional bounds of branded apparel, venturing into a realm where every stitch and seam tells a story of innovation, quality, and shared success.